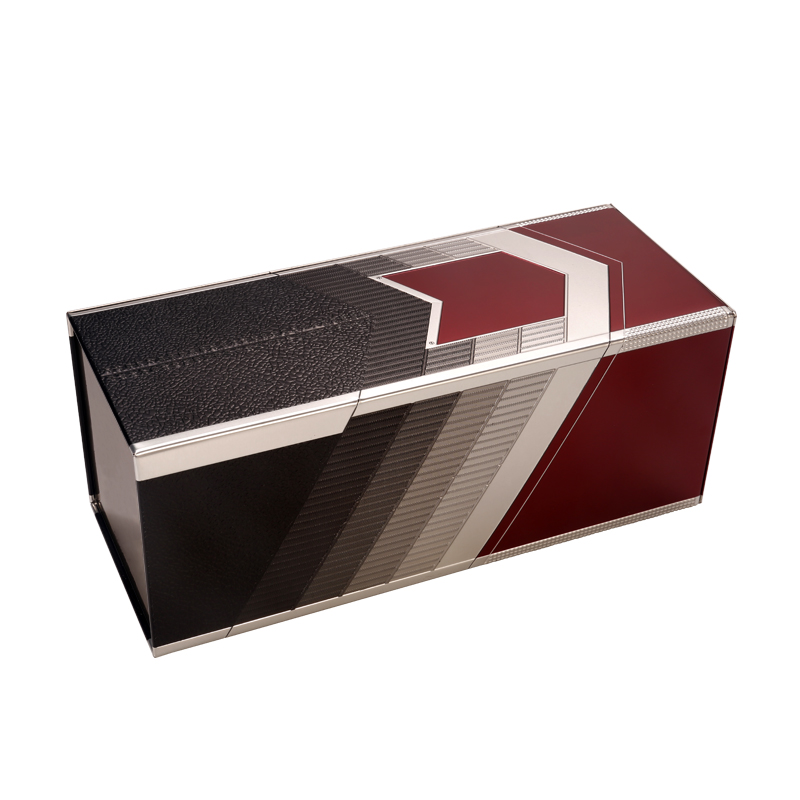

Cuboid tin box ER2032A-01 with embossing for whisky

Description

This tin box is used for holding a bottle of whisky. It is embossed in high density and high precision to create an amazing and attractive effect – leather effect.

To achieve different visual effects and feel, we can do embossing and debossing on tin boxes. We have well studied the nature of leather and achieved the leather effect on the tin box by this high-density and high-precision embossing technology. High-density and high-precision embossing / debossing by precision machine tools is a breakthrough for tin packaging and it is developed by us.

Sense of depth can be achieved by the combination of fine printing and different fine embossing / debossing, highlighting the uniqueness of the design. Leather-effect embossing / debossing on tin box reproduces visual effect of leather and good touch of leather. The difficult part is the accuracy of the molds and the accurate alignment when making a tin box. A slight deviation will cause defectives.

This amazing design adds value and differentiation to the products. It also brings the sense of luxury and help the products stand out on the store shelf, visually engage consumers and encourage them to reach hands to touch the products. See? The battle on the shelf has been almost won.

As for the printing, both CMYK and pantone are available. It can be CMYK printing. It can be pantone color printing. It can also be combination of both CMYK and pantone color printing. We have employed master experts working for over 50 years in printing industry. They can exactly figure out and mix the right colors for you.

Above the printing, there is a protection layer which we call varnish or finish. We have glossing varnish, matt varnish, glossing & matt finish, wrinkle varnish, crackle finish, rubber finish, pearl ink finish, orange peel finish, etc.

Sample lead time: Generally it takes 10-12 calendar days to make samples of tin packaging.

MOQ: We are flexible on MOQ to meet different customers’ requirements. Customer satisfaction is our highest priority.

| Materials | 0.23/0.25/0.28mm imported class A tinplate |

|

Mold Status |

More than 2000+ exsiting moulds available |

| Printing | CMYK 4C, PMS, CMYK+PMS or Customized |

|

Additional Effect |

2D or 3D Embossing, Debossing, Laser |

|

Available Accessories |

РVC/PET/APET inserts With customized compartments, EVA/Foam/Sponge with tailored cutouts, Vacuum trays, Velvet trays, paper bands, paper tags, adhesive stickers, handles, mechanism, cardboard display boxes etc |

| Packaging | Polybag/Tissue paper and export carton |

| MOQ | Up to Negotiation |

|

Delivery time |

3-5 weeks after approval of samples |

|

Price Terms |

EXW, FOB, CIF, DDU, DDP |

|

Payment Terms |

T/T, L/c, Western Union, Paypal |